Photo By

This innovative material is made from sand, cement, lime, and aluminum powder. The manufacturing process involves heating and air pressure, producing a lightweight, fire-resistant porous concrete block. Hebel comes in various sizes, with the 6600 size being the most commonly used. Its lightweight nature makes it easy to transport and install, making it a perfect alternative to red bricks in residential and commercial construction.

Hebel’s advantages lie not only in its weight but also in its adequate structural strength and excellent insulating properties. This material helps maintain a comfortable indoor temperature and saves long-term energy. With a faster and more efficient installation process, hebel has become increasingly popular among architects and contractors, making it an ideal choice for creating strong, efficient, and environmentally friendly buildings.

Types of Hebel

Hebel has become popular due to its various types and sizes, which can be tailored to meet project needs. This material comes in several types, each with unique characteristics that offer specific advantages. Here are some common types and sizes of hebel:

1. Types of Hebel

- Aerated Hebel: This type is made from a mixture containing air and offers excellent insulation properties. It is known for being lightweight and easy to install, making it ideal for various construction applications.

- Non-Aerated Hebel: This type has a higher density than aerated Hebel, providing better durability. It is suitable for buildings that require higher strength.

- Lightweight Hebel: This type is extremely light, making transportation and installation easier. It is ideal for construction projects that don't require heavy loads.

- AAC Hebel (Autoclaved Aerated Concrete): Known for the air bubbles formed through a chemical reaction using environmentally friendly aluminum paste. AAC hebel is usually white and lighter than CLC hebel.

- CLC Hebel (Cellular Lightweight Concrete): Made from conventional concrete using organic foam without a chemical reaction. This type is gray and heavier than AAC hebel.

2. Hebel Sizes

- Standard Hebel: This size typically measures 60 cm x 20 cm and has a thickness varying from 7.5 cm to 20 cm. It is most commonly used for residential walls.

- Jumbo Hebel: Larger, typically 60 cm x 40 cm, with varying thickness. Jumbo hebel is ideal for walls that require a larger surface area.

Advantages and Disadvantages of Hebel

In modern construction, lightweight and environmentally friendly materials are increasingly in demand, and hebel is one of them. This material offers various advantages in terms of efficiency and durability, but it also has some disadvantages that should be considered. Below is a detailed explanation of the advantages and disadvantages of hebel as a building material.

Advantages of Hebel

- Lighter Weight and Easy Installation

One of the main advantages of hebel is its lighter weight compared to traditional materials like red bricks. This makes transportation easier, reduces shipping costs, and speeds up the installation process at the project site, resulting in time and labor efficiency.

- Environmentally Friendly and Supports Energy Efficiency

Hebel requires fewer raw materials and less energy during production, making it an environmentally friendly choice. Additionally, its heat-insulating ability helps save energy for heating and cooling spaces, contributing to efforts to reduce carbon footprints.

- Effective Sound and Heat Insulation

Hebel’s insulating properties make it ideal for reducing noise from the outside and maintaining a stable indoor temperature. This feature makes it suitable for areas requiring sound privacy and buildings that need stable room temperature conditions.

- Good Durability Against Fire, Termites, and Mold

Hebel's resistance to fire, insects, and mold enhances its long-term durability. Buildings made with hebel are better protected from external factors that damage building materials, including earthquake vibrations.

- Larger and Uniform Size

With larger dimensions than regular bricks, hebel allows for faster installation and smoother walls. In addition to improving the aesthetics of the building, its uniform size helps speed up project completion.

Disadvantages of Hebel

- Higher Material Cost

Although installation is fast, the price per unit of hebel is higher than that of red bricks. This cost should be carefully considered, especially for projects with a limited budget.

- Lower Strength in Supporting Heavy Loads

Hebel has a lower compressive strength than reinforced concrete or red bricks, making it less ideal for structures that require high load-bearing capacity. The use of Hebel in multi-story buildings or heavy structures needs to be carefully planned during construction.

- Requires Skilled Labor for Installation

Skilled professionals must do hebel installation, as the material is fragile and can crack easily if not handled properly. Using the right adhesive and installation techniques will help maintain its durability.

- Prone to Cracking and Deterioration in High Humidity

Hebel tends to absorb water, making it vulnerable to cracking or rotting when exposed to excessive moisture. To preserve its quality, additional protection, such as waterproof coatings, is highly recommended.

Differences Between Hebel and Red Bricks

Hebel and red bricks are both popular choices for wall construction. They serve the same purpose, but they differ significantly in terms of manufacturing, weight, insulation, and cost, which affects their overall effectiveness and efficiency.

- Material and Manufacturing Process

Hebel is made from a mixture of sand, cement, and other additives through a controlled, modern process, resulting in a uniform and lightweight structure. In contrast, red bricks are produced by firing clay, giving them a natural texture and traditional characteristics.

- Weight Difference

Hebel’s lightweight nature makes transportation and installation easier, saving time and labor. On the other hand, red bricks are heavier, requiring more effort during installation, although their weight provides greater resistance to pressure.

- Insulation Properties

Hebel excels in sound and heat insulation, helping maintain stable room temperatures and improving energy efficiency. While red bricks are less effective in insulation, they still provide good durability for building structures.

- Cost Comparison

Red bricks are more economical in terms of price, costing around Rp650 per piece, whereas hebel can cost up to Rp6,000 per piece. Although hebel is more expensive per cubic unit, the faster installation time and labor savings often offset this cost difference.

Use of Hebel

Hebel is widely used in the construction industry for various buildings, including residential homes, office buildings, schools, and hospitals. This material suits exterior walls, partition walls, floors, roofs, and architectural elements like windows and doors. Its lightweight nature and excellent insulation properties make hebel an ideal choice for residential projects, multi-story buildings, and renovations, as it is easy to install and its size is flexible for adaptation. Hebel supports efficient, high-quality, and energy-saving construction, making it a modern solution in the industry.

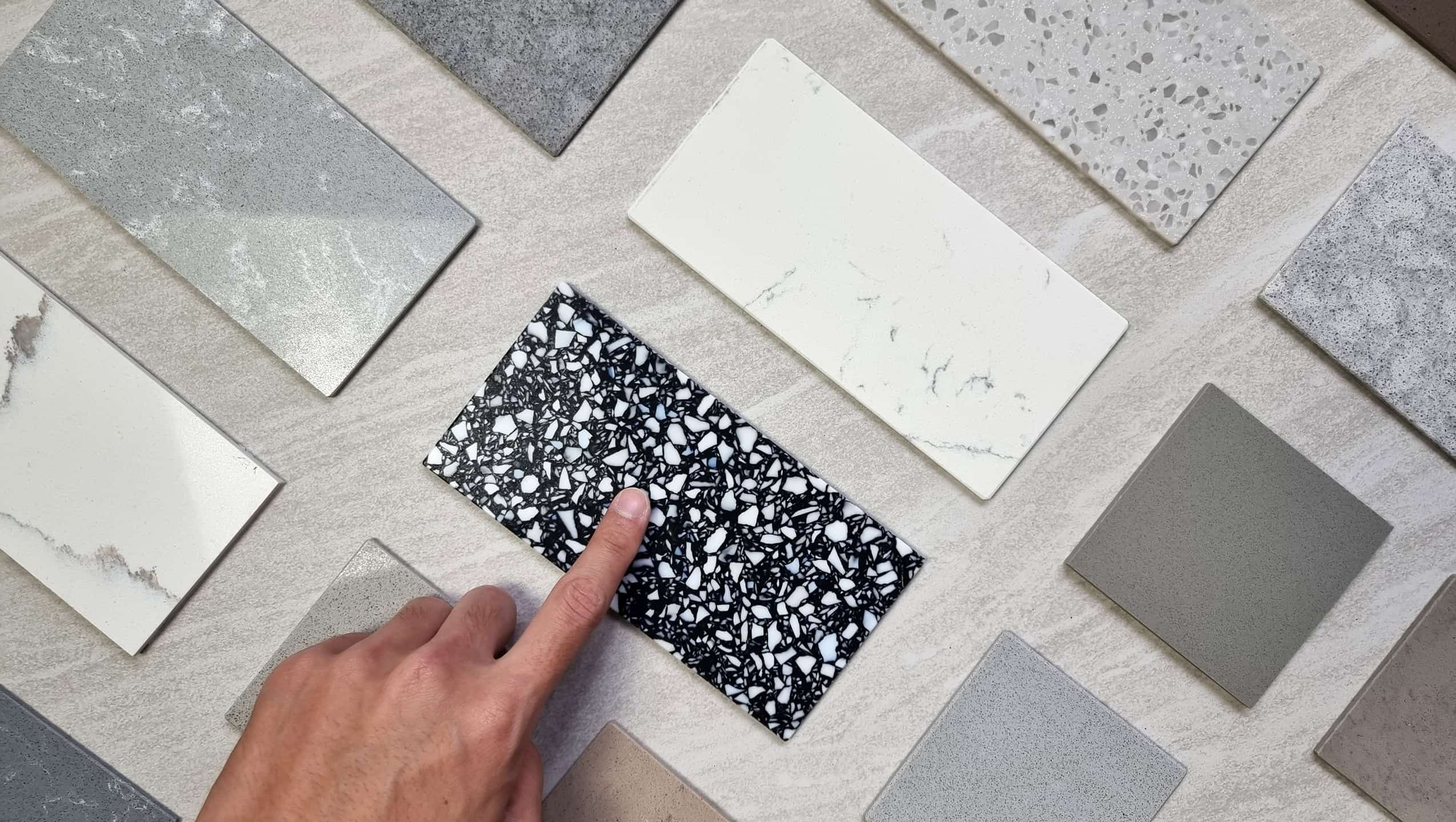

Thus, hebel becomes an innovative solution for strong and efficient buildings. For even better results, combine it with MAGIA Granite, which offers modern aesthetics and high durability, making every corner of your home look more luxurious and high-quality.

Popular Collections